¿Necesitas un lijado de precisión sin dañar superficies delicadas? Descubre las ventajas del disco de espuma estándar...

}The EKAMANT company is a Swedish manufacturer of flexible abrasives, with more than 90 years of experience. It is a prestigious company, recognized for its high quality in the manufacture of antistatic abrasives, on paper support, for the wood and varnishing industries; as well as for its great experience in the world market.

The company was founded in 1928 and is located in Markaryd, a small town in the heart of the Swedish forests. The knowledge accumulated throughout all these years of existence has been transmitted from generation to generation. Today the combination of tradition, technology and technical support, to its specialized international network of transformers, is the key to its success.

EKAMANT invented the first antistatic abrasive on the market in 1975. This innovation achieves a sanding with a low electrostatic charge, leaving the dust-free of charge, facilitating its aspiration and achieving excellent results in the performance of abrasives and the final surface finish.

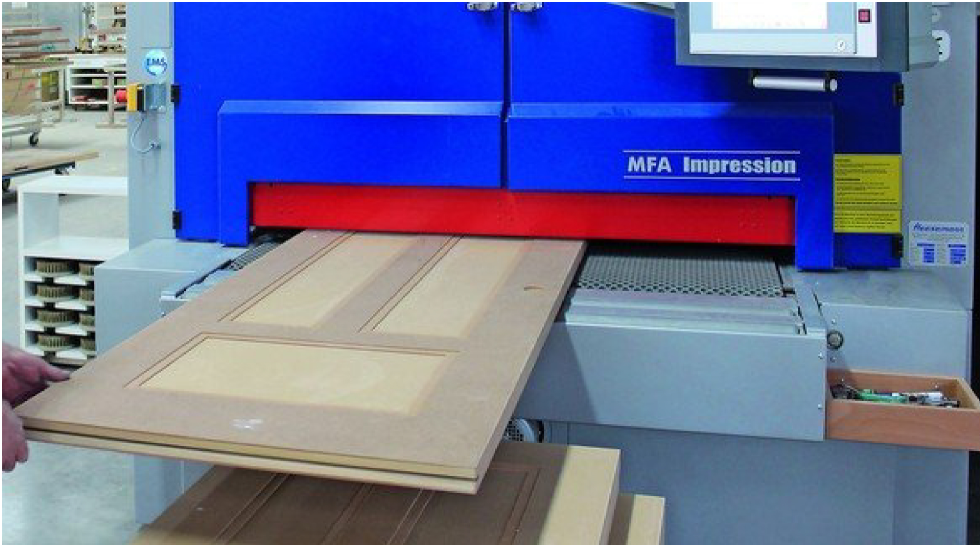

As a result of its high specialization in sanding, its abrasives are manufactured to meet the specific needs of the different materials present in the wood and varnishing industries:

Fiberboards and particle boards.

Plywood and OSB boards

Hardwoods

Soft and resinous woods

Lock

Melamine

Varnishes and lacquers

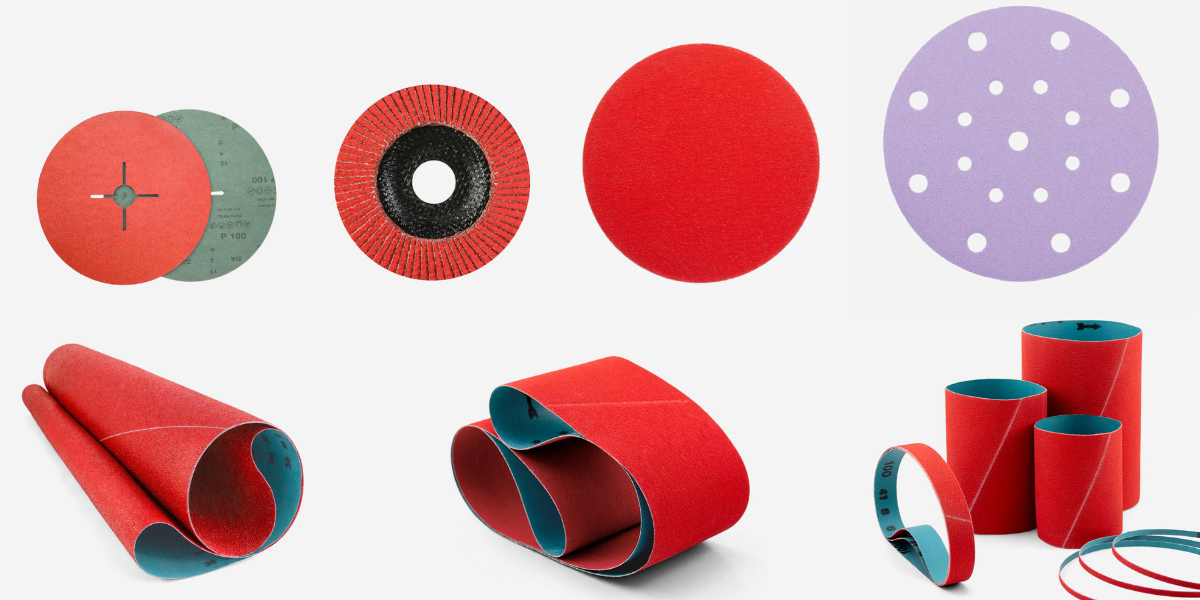

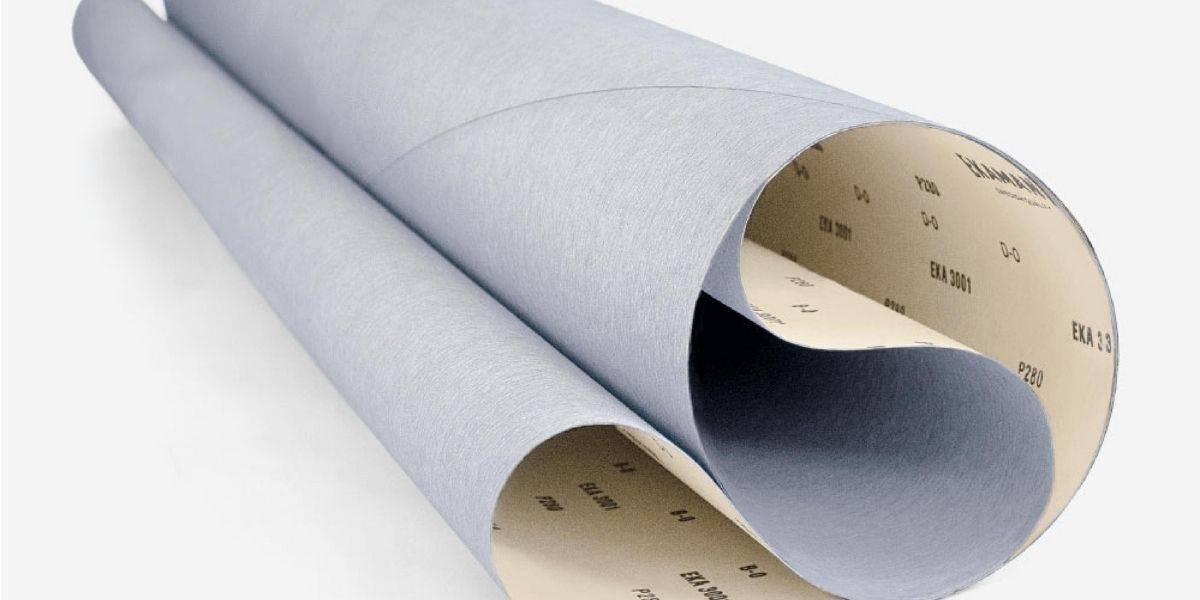

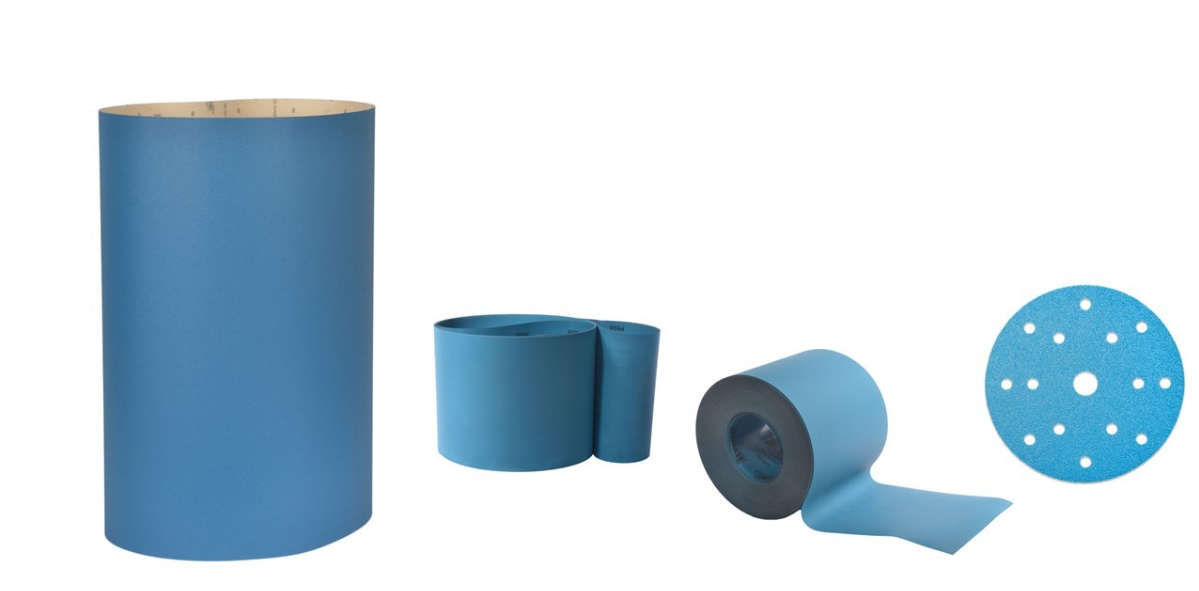

Although EKAMANT has a complete range of abrasives on different supports: paper, fabric and film, it is the paper-backed abrasives for the transformation into belts that stand out from their competitors due to their high quality, uniformity and price.

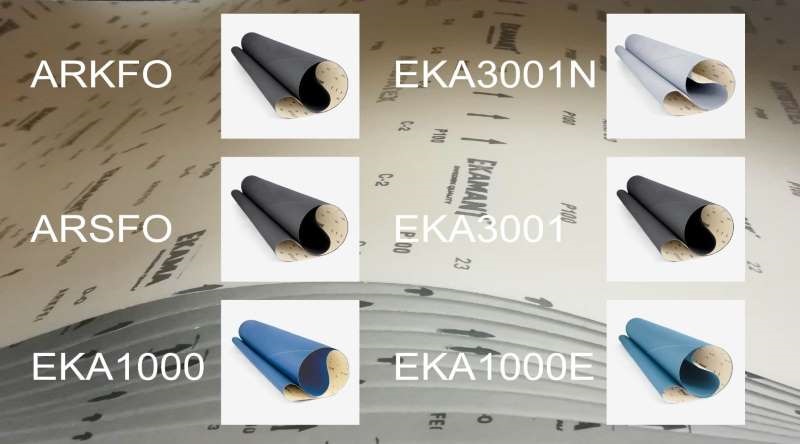

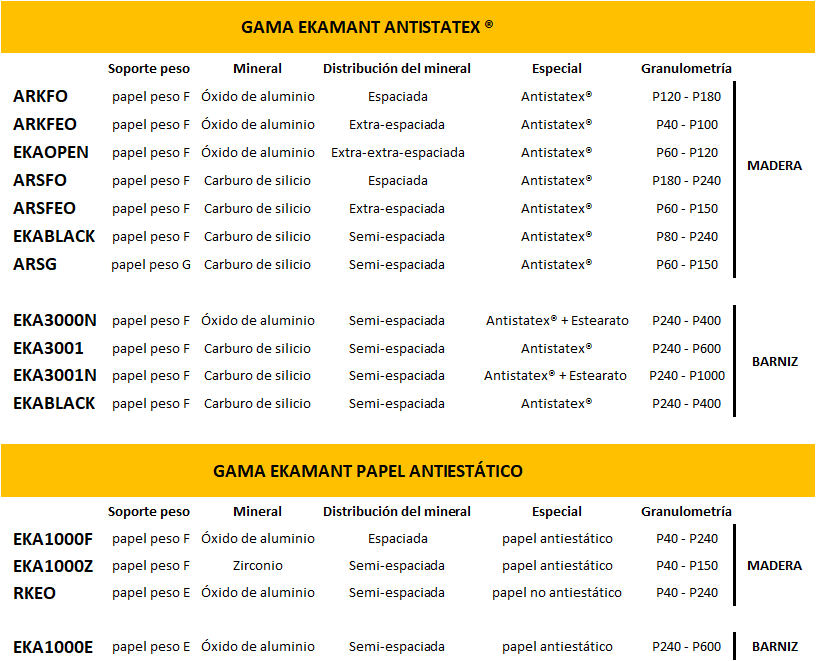

We refer to the Ekamant line of premium abrasives with ANTISTATEX® treatment, and the line for universal use with an antistatic effect on paper support.

EKAMANT ANTISTATEX® abrasive line

The Ekamant Antistatex® abrasive range is made up of the brand's star products: ARKFO, ARSFO, ARSG, EKABLACK ..., abrasive papers of weights F and G with high stability, to be transformed into paper sanding belts for machine work calibrators, flat sanders and sanders with cross units for the finest finishes.

These abrasives are made with binders of one hundred percent phenolic resin, which makes them more resistant to temperature increases that occur during sanding and changes in humidity in the environment. The result is a longer life of the abrasive belt.

The minerals used are of great purity, which facilitates a greater cutting capacity, generating a clean and fine cut of the wood fiber, providing a surface with a little puncture and very uniform.

All the abrasives in this range incorporate an antistatic treatment, Antistatex®, in the last layer of resin that covers the mineral; efficiently avoiding the generation of electrostatic charges during sanding on the dust and the sanded piece.

This antistatic treatment consists of achieving that the abrasive belt has electrical conductivity, and acts as a conductive material offering low resistance to the passage of current through the abrasive surface. For this, highly conductive graphite powder particles are mixed with the phenolic resins. As a result, the electrostatic charges that are produced are derived through the abrasive and the machine.

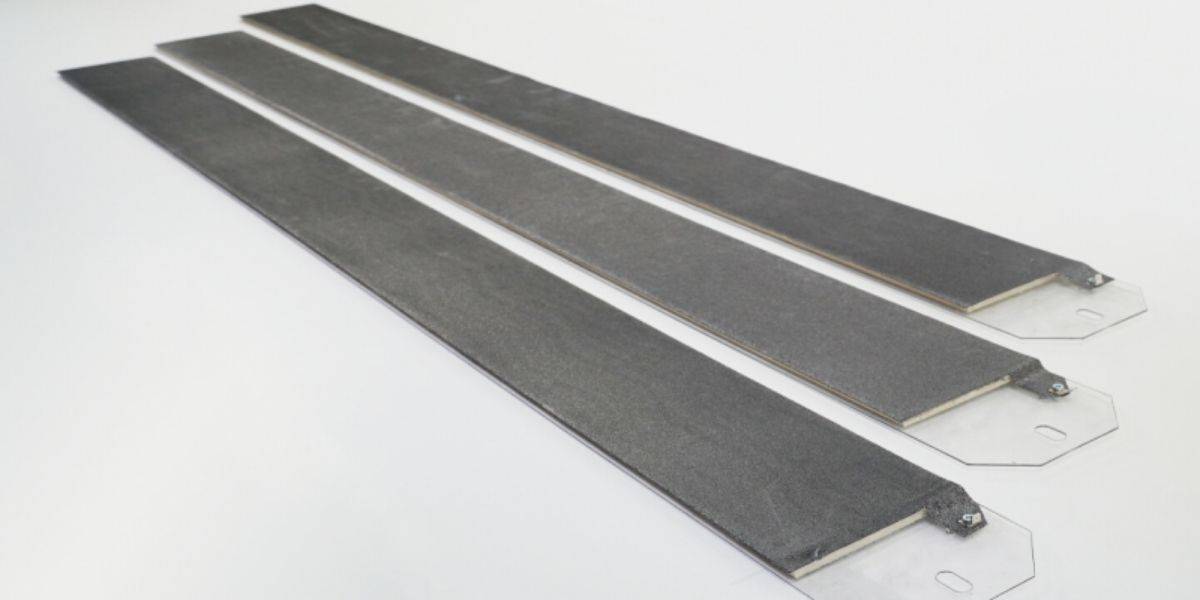

EKAMANT abrasive line with ANTISTATIC PAPER

The range of abrasives for universal use and with support with antistatic effect: EKA1000F, EKA1000E and EKA1000Z, is made up of abrasives with different paperweights, with weights F and E, for a better adaptation to the different applications of machine sanding, which require semi-rigid and flexible supports depending on the type of operation to be performed.

Like the abrasives in the Antistatex® range, they are made entirely of high-quality phenolic and mineral resins.

In the products of this range, the paper support has been previously treated to give it a higher conductivity that helps to minimize electrostatic charges in the dust and on the sanded surface.

The EKAMANT company is a manufacturer of high-performance abrasives, a key partner that adds value to its distribution network by sharing its knowledge and providing technical coverage to its collaborators and customers present in more than 50 countries.

At Abracom, we have been collaborating with the EKAMANT brand for more than 35 years, transforming its raw material into abrasive belts tailored to the industries and manufacturers of the Spanish market. Like the EKAMANT company, we share values such as commercial seriousness, commitment to manufacturing deadlines and technical support for our clients.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)