¿Necesitas un lijado de precisión sin dañar superficies delicadas? Descubre las ventajas del disco de espuma estándar...

}When we go to buy a belt sander, we look for information on specialized websites, on buying guides, opinion pages and comparative tables between models and brands. We care about knowing in detail all its characteristics:

tool power and resistance

the possibility of having different speeds

how the working speed is regulated

safe design and ergonomics of the handle

the weight of the machine and the precision of work that it allows us.

the ease of changing the abrasive belt without using tools

if it has screw clamps to be able to fix it to a bench

the suction system and the dust bag changing system.

if you have a cover or box for transport and conservation

and of course the manufacturer's brand and the discounts or promotions available at that time. However, we completely forget about the sanding belts necessary for its operation.

What essential aspects should I know about a sanding belt?

The use of belt sanders is very widespread in the professional and DIY or private fields. For this reason several expressions are used to refer to the sandpaper consumable.

The most common names are sanding belt or abrasive belt, but also cloth sanding belt, sanding belt or sanding belt.

The basic data to identify a sanding belt are its dimensions and the size of the grain. The dimensions, width and length, are usually expressed in mm and generally for most portable belt sanders on the market they range from:

Width: between 75 and 100 mm

Length or development: between 450 and 600 mm

The size of the abrasive grain is another variable to consider. However, many users are unaware of the numbering or complete series of grains that exist for professional use.

In order of grain size, from coarsest to finest, the consecutive grains grading according to the European FEPA standard is 16, 24, 36, 40, 50, 60, 80, 100, 120, 150, 180 and 220. This series of macro grains is complemented by the series of micro grains 240, 280, 320, 400, 500, 600, 800, 1000, 1200, 1500, 2000 and 250, although the latter are not those used in work with a sander belt.

Each grain size is appropriate for a type of sanding operation:

Aggressive sanding, calibrating, roughing: grains 24, 36 and 40.

Coarse sanding, brushing: grains 50, 60 and 80.

Intermediate sanding, finishing: 100, 120 and 150 grain

Fine sanding, finishing: grain 180 and 220

The sequence of grains to be used is a factor that directly influences the finish of the sanded surface and the performance of the abrasive itself. In this sequence, the grain with an immediate larger size is capable of regularly reducing the level of roughness generated by the previous grain, maintaining an adequate level of performance. As far as possible it is recommended to carry out a sequence of consecutive grains.

What is the most appropriate joint for portable belt sandpaper?

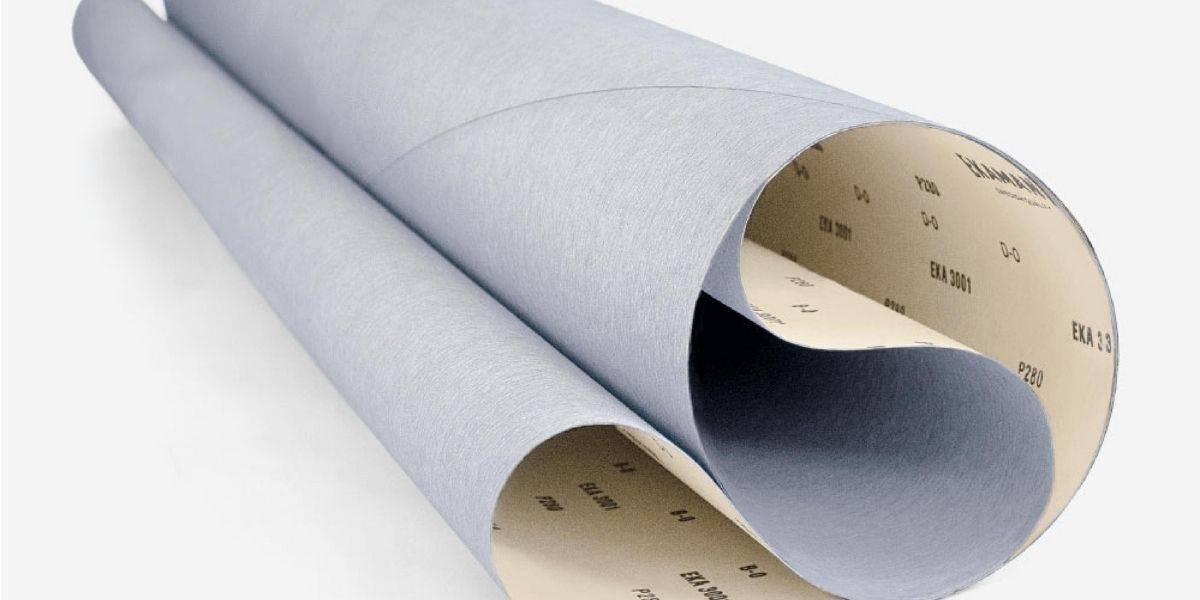

A portable sanding belt is an abrasive with a generally cloth backing, and in the form of an endless belt or band whose ends are joined together to form a joint or joint.

The most common type of joint with which these sanding belts are manufactured is the one with the ends overlapping each other and with the abrasive mineral, from the joint area, lowered or completely eliminated. We must bear in mind that fabric, unlike paper (pressed cellulose layers), is a fabric of threads that frays when cut, does not maintain a uniform thickness and loses its initial shape.

To compensate for these irregularities, the grain is reduced or killed to prevent the thickness of the joint from standing out from the thickness of the tape itself. In case of protrusion, vibrations or jumps will occur during sanding work, and marks in the form of blows of the joint on the sanded surface.

Another type of joint also used is what is called a butt joint. On this occasion, the ends of the tape are joined together with a polyester tape adhered by the part of the support of the belt. This type of gasket is commonly used for metal sanding applications.

What are the most suitable types of supports for belt sandpaper?

Support is another important variable to consider, especially in the DIY sector where the supply of supports that supply stores offer is very limited, focusing on basic options. However, it is important to know which are the most suitable fabric supports for the work we are going to carry out. In general terms, the stiffer support, the higher the performance of the abrasive mineral that it has anchored. Similarly, the greater your ability to plan the surface and not copy existing imperfections.

According to the type of operation to be carried out, the most suitable supports are:

semi-flexible cotton fabrics, called J-fabrics, are used for sanding smooth contours and profiles.

For rough or intermediate sanding of surfaces and/or edges, rigid cotton fabrics are used, called X fabrics.

For aggressive sanding of the surface and/or edge, rigid polyester and cotton fabrics, called XY fabrics, are recommended. In these fabrics, the cotton fibers have been impregnated with a polyester resin that gives them greater resistance.

for jobs that require wet lubrication, supports with rigid polyester fabrics that are fully waterproof, called Y or YY fabrics, are recommended.

What type of mineral is the most appropriate?

The type of mineral to be used is conditioned by the sanding operation and the type of material to be sanded. Generally, applications and operations with portable belt sanders do not require high mechanical stress where cutting speeds are high and high working pressures are required.

For this reason, aluminum oxide is, without a doubt, the most widely used mineral for this type of belt thanks to the fact that it is a universal mineral valid for different applications in wood and metal, it has a perfect combination of resistance and hardness, and is ideal for intermediate and finishing sanding.

For information, it should be noted that there are other minerals on the market such as silicon carbide, zirconium, compact mineral, ceramics and the pyramidal type.

For the most common works, we recommend the use of:

Aluminum oxide: wood, sheet metal, melamine, leather, iron.

Silicon carbide: varnishes, glass, stone, marble, granite, ceramic, rubber, plastic, bronze, copper, brass.

Zirconium: stainless steels, aluminum, zamak, cast iron

At Abracom we are manufacturers of custom sanding belts for professional use. We are specialists in belts for all industries. We have all the supports, types of minerals and types of joints.

.png)

.jpg)