¿Necesitas un lijado de precisión sin dañar superficies delicadas? Descubre las ventajas del disco de espuma estándar...

}1. What is surface conditioning?

Surface conditioning is a three-dimensional abrasive. It is made up of nylon fibers intertwined like a skein, impregnated with resin and abrasive minerals. This fabric is anchored on a non-woven fabric support.

The open structure of the impregnated fiber yarns allows new abrasive minerals to be released during use, which reduces the heating of the surfaces, avoiding deformations and/or color changes of the surfaces.

Surface conditioning abrasives have been developed to offer the highest quality in terms of performance, cutting capacity and surface polishing.

2. Advantages of surface conditioning

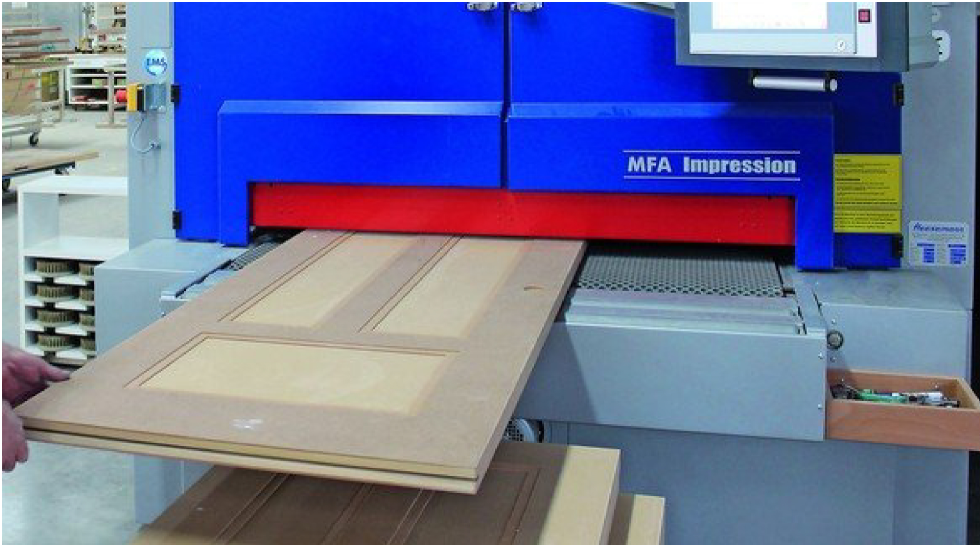

In general terms, we can say that surface conditioning abrasives, regardless of the type of format (belt or disc), improve the quality of finishes and increase the productivity and efficiency of industrial processes.

Its many advantages include:

They offer more regular and uniform finishes.

They save time and money by reducing the sequence of steps required to achieve the desired finishes and polishes.

Thanks to their different degrees of flexibility and density, they integrate in a single product high performance, good cutting capacity and an excellent finish level.

Thanks to their three-dimensional open structure, they avoid problems of deformation or discoloration of the surfaces.

The treated surfaces have a superior finish quality compared to conventional abrasives: the absence of scratches, marks and burrs.

3. Sectors and applications of surface conditioning

The main field of application of surface conditioning abrasives is cleaning, finishing and polishing of metal surfaces; especially those of stainless steel and aluminum. Although they can also be used for work on fiberglass, plastic, resins and composite materials.

At a process level, surface conditioning products are ideal for semi-roughing, finishing and satin finishing of surfaces.

4. Sales formats

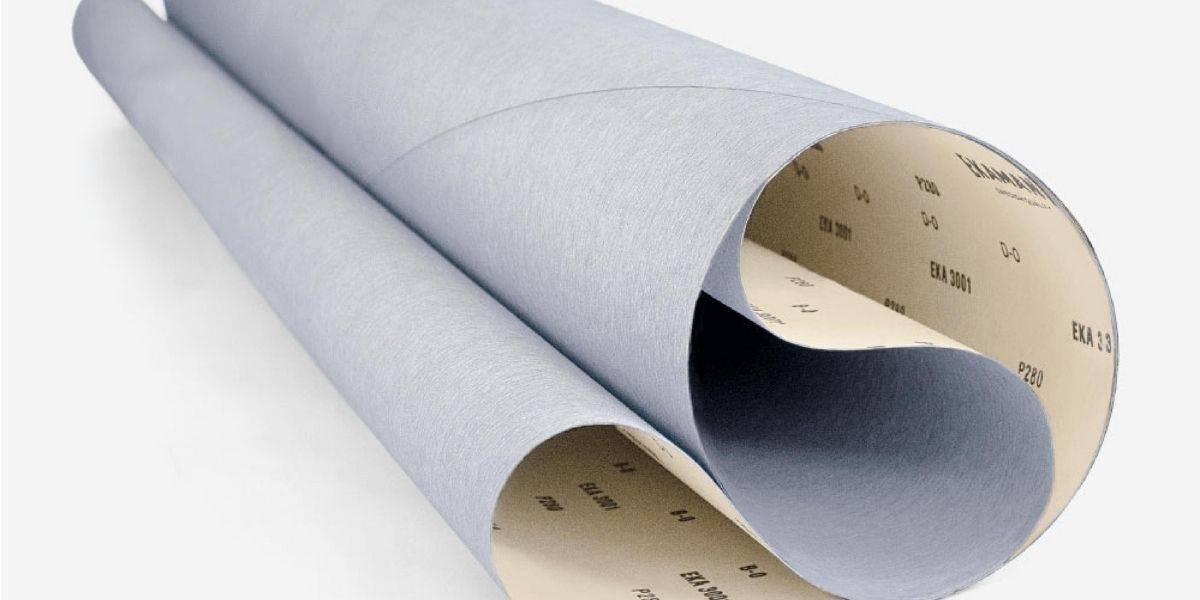

Surface conditioning abrasives are found on the market mainly in belt and disc formats. In both cases, the starting point is a coil or jumbo roll of raw material that is later transformed into bands and/or discs.

4.1. Bands

In the band format, there are different types of supports depending on the rigidity or flexibility required by the type of machine where they will be used and the cutting requirements of the work to be carried out.

We can differentiate the following options:

Flexible band support - ideal for measuring small bands, mini bands and sleeves used on portable machines.

Rigid band support: suitable for most operations where bands are involved. The rigidity of the support prevents elongation of the belts while working.

Extra rigid band support: suitable for the most aggressive applications. It is characterized by having a high resistance to elongation and a high cutting power.

4.2. Discs

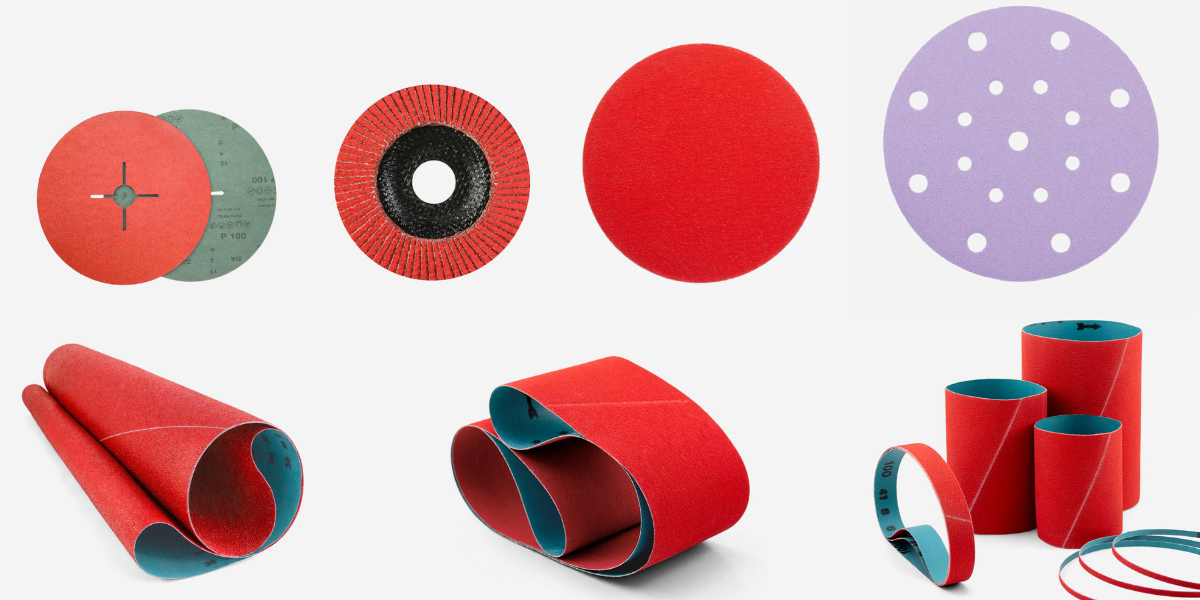

In the discs, the available options are very varied and have a wide assortment of different formats for work with a portable grinding machine:

Velcro discs, without or with a central hole for fixing with a nut on the platter.

Extra rigid discs with velcro, without or with a central hole for fixing with a nut on the plate.

Discs with vulcanized fiber support for fixing with a nut on plate.

Discs with quick-change system.

Surface conditioning flap discs.

5. Granulometry

Surface conditioning abrasives use a different grain size than that used in conventional abrasives with cloth or paper backing. In this case, the different degrees of finish are expressed through the following scale:

COARSE – MEDIUM – FINE – VERY FINE – ULTRAFINE

The grain equivalence between this nomenclature and the traditional FEPA is as follows:

COARSE MEDIUM FINE VERY FINE ULTRAFINE

P80 P100 – P120 P150 P180 – P220 P280 – P320

In the case of the extra rigid surface conditioning supports, for the most aggressive operations, the equivalences are different:

COARSE MEDIUM

P50 - P60 P60 – P80

The ULTRAFINE grading is manufactured from silicon carbide ore, while the rest are made from aluminum oxide ore. Depending on the manufacturer, each granulometry is identified with a different color. In general, we can be guided by the following colors:

COARSE MEDIUM FINE VERY FINE ULTRAFINE

brown garnet green blue gray

At Abracom, we are highly specialized and manufacture surface conditioning belts for the highest quality work on metal surfaces. We have the necessary technology to manufacture from mini-bands and sleeves, narrow bands and long bands of surface conditioning with a fast delivery time.

.png)

.jpg)