¿Necesitas un lijado de precisión sin dañar superficies delicadas? Descubre las ventajas del disco de espuma estándar...

}What is an abrasive wheel and how is it different from other abrasives.

These are abrasive tools with a circular shape, which wear uniformly around their perimeter and adapt easily to complex contours and shapes; facilitating sanding operations with a constant finish.

Unlike conventional flexible abrasives, abrasive wheels have a three-dimensional construction. Its structure is formed by a support of "non-woven" nylon fibers, like a skein, which are impregnated with synthetic resins and abrasive minerals.

By combining the different elements we can obtain abrasive wheels with different densities and hardnesses, as well as different cutting and finishing capacities. In this way we can control the damping action of the wheel and dose the sanding pressure to the type of material we want to sand

What are abrasive wheels for?

Abrasive wheels are of great importance for industries that perform surface treatment through mechanical processes. In these industries, products are demanded that solve the main problems that arise in automatic or semi-automatic machines: constant cutting power, long life and uniform finish.

They are also used in portable electric, pneumatic, and flex-shaft machines for grinding, cleaning, and satin finishes.

Furthermore, at an industrial level, a wide range of products is required to suit each type of material; as well as the different applications to be carried out:

Lapping, deburring, grinding and trimming.

Sanding, finishing and polishing.

Satin.

Cleaning.

What materials can they treat

Abrasive wheels are used for finishing operations on the following materials:

Raw wood and MDF

Wood and varnished melamine papers

Metals

Ceramic and stoneware

Printed circuits

Raw wood and MDF

They are ideal for the processing of raw wood and its substitute products such as MDF, as they are able to perfectly conform to the profile, maintaining excellent performance until complete exhaustion. They are used in sanding door frames, baseboards and moldings.

Wood and varnished melamine papers

Paint sanding processes are generally very demanding, and require abrasive wheels suitable for both the type of varnish that covers the surface and the desired finish. The variety of varnishes used today is very wide: polyurethane-based varnishes, acrylics, UV polyesters, etc.… with open, closed, aged pore finishes, etc.

The customization of the abrasive wheels allows the user to achieve the desired level of finish without damaging the surfaces painted with one or more coats of paint.

Metal

The metal sector is very broad and diverse, and therefore requires a complete range of abrasive wheels for all operations, from primary grinding and sanding, to finishing, polishing and satin finishing.

In many cases, handled products require delicate finishes such as profiles, decorative accessories, visible surfaces of household appliances, as well as for finishing stainless steel sheets and coils.

Abrasive wheels are manufactured both for the sanding of hard metals, where durability, abrasive capacity and a glossy finish prevail; as for finishing soft metals; for example, those used in spectacle frames, precision surgical instruments, watch components, jewelry, etc.

Ceramic and stoneware

The use of abrasive wheels for the processing of ceramic, porcelain stoneware, marble and granite is mainly concentrated in the final work on the edges of the piece.

Printed circuits

Abrasive wheels are also used to clean and deoxidize printed circuit boards without leaving any dirt.

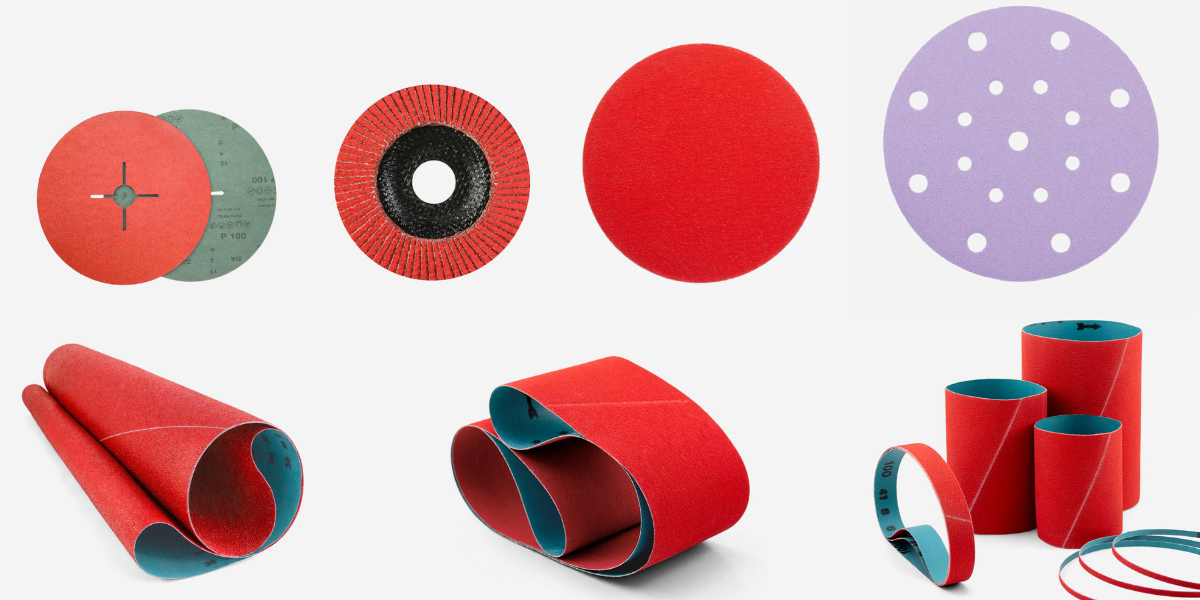

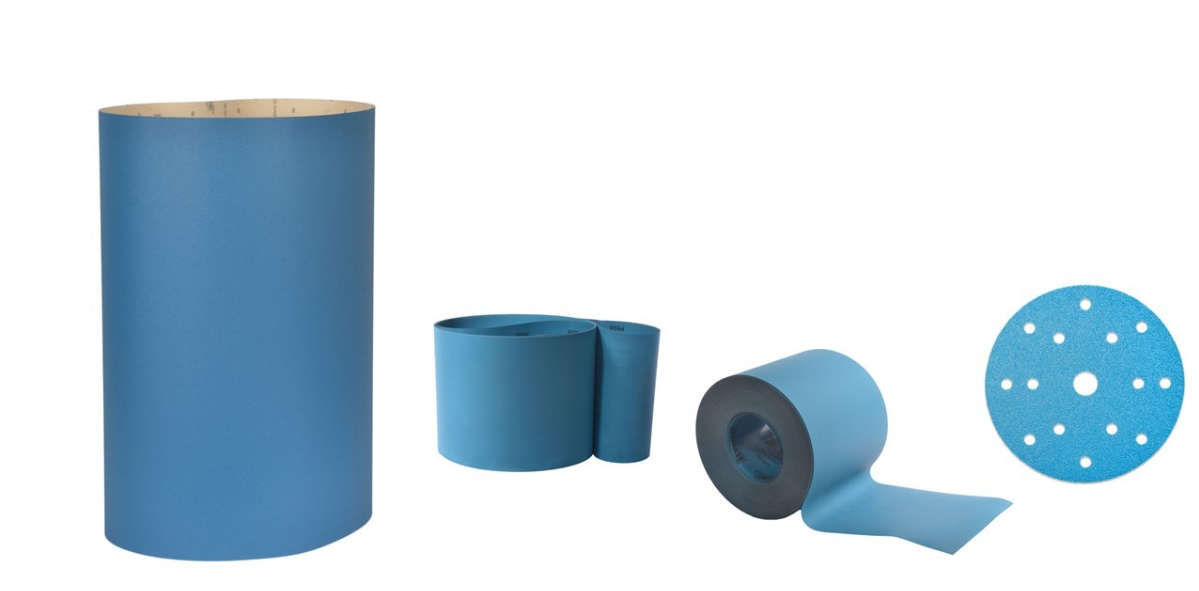

Types of abrasive wheels

We have abrasive wheels in different diameters, grades and densities.

They are available both in the flanged version with a central core to be mounted on the different bench machines, and with a 3 or 6 mm steel shaft for the different portable machines.

Three main types of abrasive wheels

Compact abrasive wheels: "CONVOLUTE"

Compact abrasive wheels or also called "convolute" are formed by wrapping nonwoven fiber material, better known as "non-woven" abrasive around a central core and bonding the layers together to create an abrasive wheel.

Abrasive flap wheels: "FLAP"

Similarly, non-compact abrasive wheels or, also called "flap abrasive" wheels, are made up of sheets of nonwoven abrasive fiber mounted side by side around a central core. This construction makes these wheels one of the best solutions when it comes to adapting to different shapes.

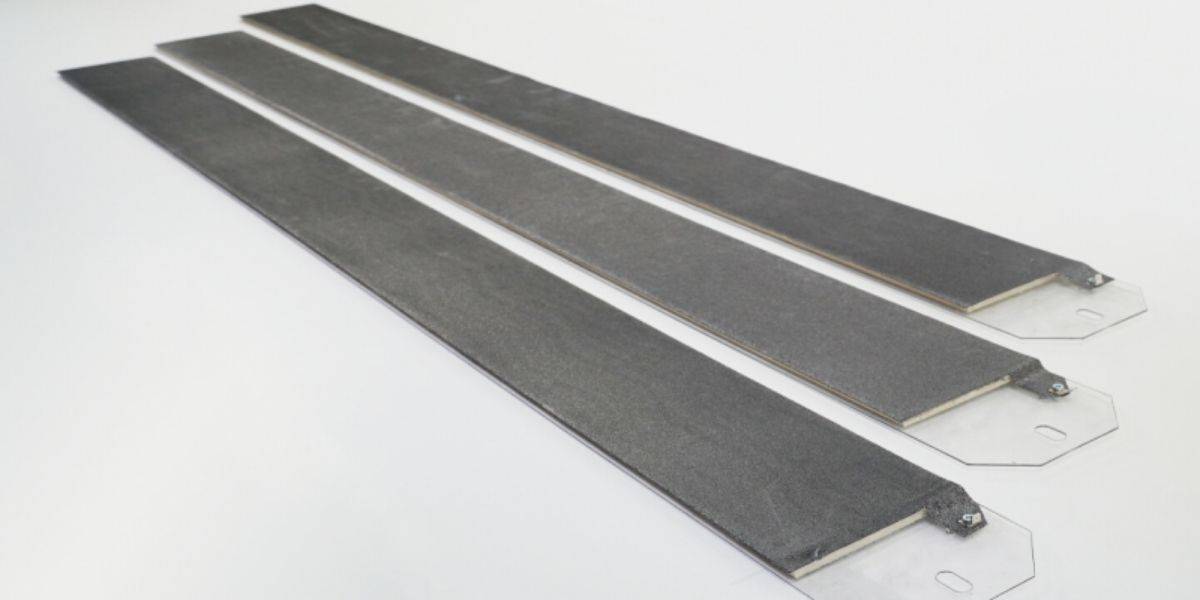

Abrasive wheels with cloth or paper blades: "MIXED FLAP"

Some wheels intersperse sheets of abrasive fiber with sheets of cloth or abrasive paper. These flap wheels are more aggressive than those with only fiber. They offer a higher cutting ratio. The ratio of sanding sheets to fiber sheets can be modified to suit different applications. They are less conformable, and therefore more rigid and serve to quickly remove more material. They should always be used in the direction indicated by the arrow on the product label.

There are two minerals used for the manufacture of abrasive wheels:

Aluminum oxide mineral

Aluminum oxide is a high-performance mineral that is resistant in use. It is less sharp and recommended for high-speed sanding, it can be used in both the wood and metal sectors.

Silicon Carbide Ore

Silicon carbide ore has very sharp edges. It is very aggressive, but at the same time fragile so it breaks easily, generating new, sharper edges. This mineral is used for the most demanding finishes with very fine, ultra-fine and micro-fine levels of roughness.

The work with abrasive wheels requires technical knowledge, specific in terms of abrasives, working speeds and pressure.

When choosing abrasive wheels we must assess the following aspects:

The shape of the piece.

The difficulty of the profile to be treated.

Size and accessibility of the work area.

Available means: machines and tools.

Characteristics and properties of the material of the piece.

The initial state of the surface.

Final finish that we want to obtain.

At Abracom we are specialists in these tools. If you have questions or a specific need, for more information on grinding wheels and other products for professional sanding.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)