¿Necesitas un lijado de precisión sin dañar superficies delicadas? Descubre las ventajas del disco de espuma estándar...

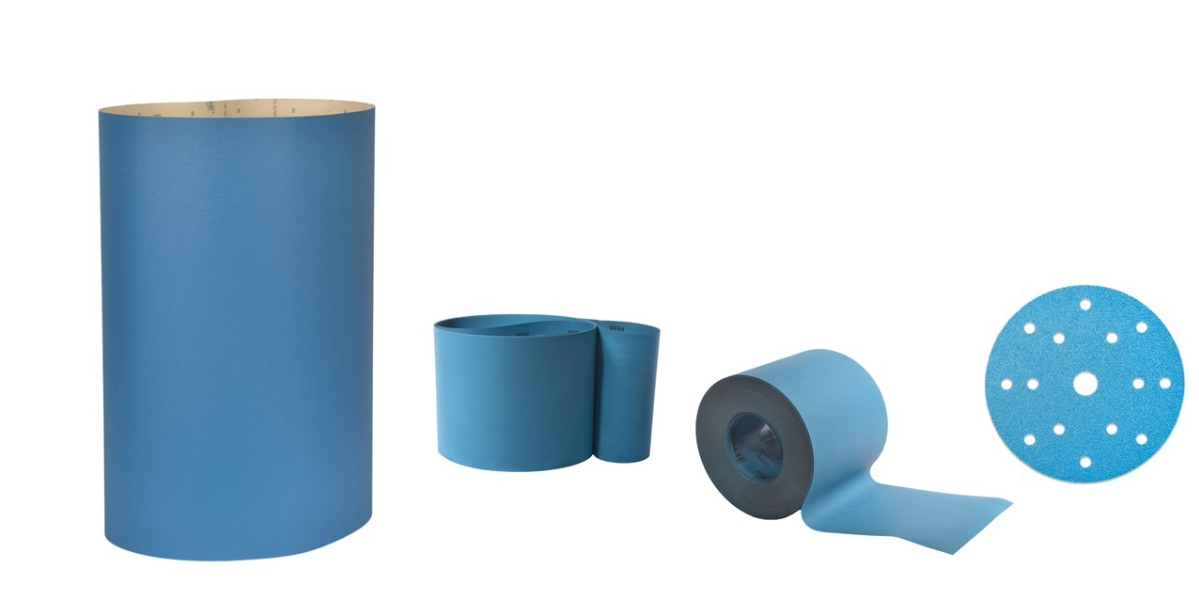

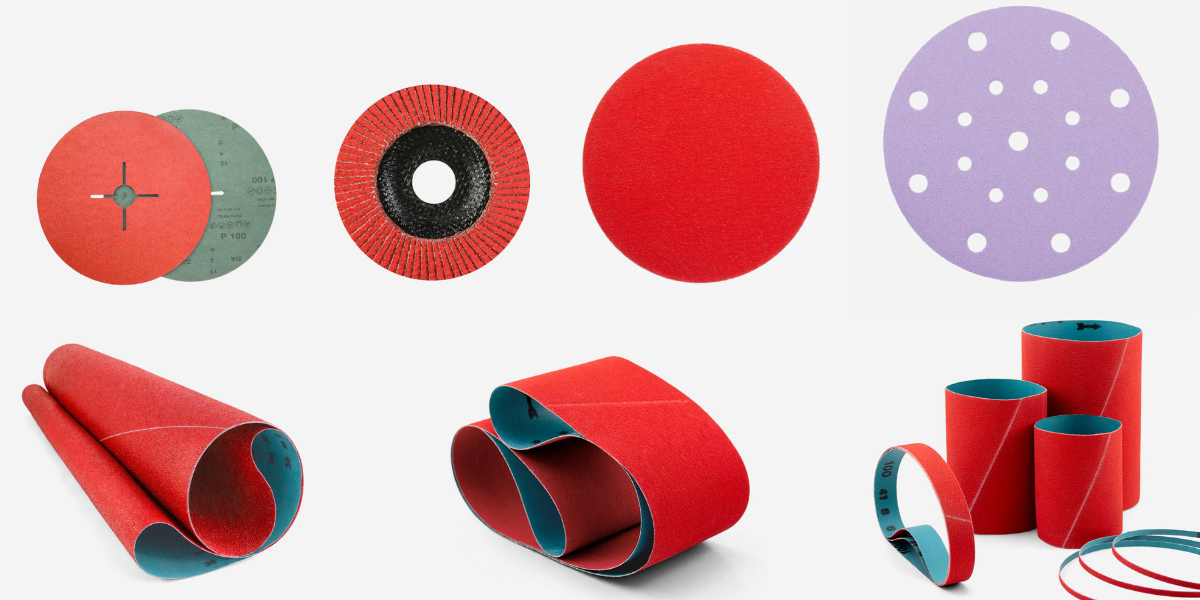

}Abrasive products coated in roll, disc and abrasive belt format are used in the main industrial sectors such as the automobile industry, the nautical ndustry, wood and varnishing, construction, and painting and decoration,among others.

These abrasive materials are widely used and high consumption. In fact, we can affirm that in the majority of cases in which there has been a process of painting a surface, it has previously been subjected to a preparation process in which a coated abrasive product has been used.

Coated abrasive products are used in most surface preparation

processes for painting

Abrasive products: basic recommendations for choosing them

Because the market offers a multitude of options for abrasives transformed into rolls, abrasive discs and sanding bands, when choosing the most appropriate one, we must take into account some considerations:

Aspects to consider in the selection of sandpaper rolls

Accessibility to the work area, comfort and convenience for the user during the sanding operation, the type of material to be sanded, the sanding operation to be performed and the price variable are the main factors that condition the use of a type of sandpaper or other roll.

According to the type of support or backing material of the abrasive rolls wecan classify them into:

Sandpaper rolls with flexible or rigid paper support. Optimal for any universal sanding and all kinds of metal, wood, varnish, resins and solid surface parts among others

Sandpaper rolls with sponge paper support. Excellent for sanding profiles, moldings

and curved surfacesSandpaper rolls with velcro paper holders. Necessary for manual sanding with the help of coves and claws.

Sandpaper roll with flexible, semi-flexible or rigid fabric support. Use for universal sanding of all types of materials, in which the performance of the abrasive takes priority over the final finish.

Sandpaper rolls of non-woven fiber (scotch). Employees for surface shading.Abrasive products coated in roll, disc and abrasive belt format are used in the main industrial sectors such as the automobile industry, the nautical industry, wood and varnishing, construction, and painting and decoration, among others.

Rolls of steel wool sandpaper. Used to achieve an excellent finish on varnished and difficult to access surfaces, which in turn will be finished in high gloss.

Aspects to consider when choosing discs and sheets

1 Format of the abrasive disc:

When choosing the abrasive disc we must take into account:

The type of fastening of the disc to the plate, among which are:the velcro system, the self-adhesive system or the system without fixing by the support part.

The outer diameter and the number of holes. Variables that must match the diameter of the plate and the number of holes in it.

2. Types of operation to perform.

Coarse sanding of surfaces (grains 40, 60 and 80) corresponds to discs with a support of rigid paper or polyester film.

Intermediate sanding of the surface (grains 100, 120, 150, and 180): it corresponds to discs with support on semi-rigid or flexible paper depending on the needs of adaptation to the surface that we are going to sand.

Fine sanding (grains 220 to 600) we will opt for discs with a flexible paper backing or polyester film.

Finishing sanding (grains from 600 to 2000). In this case, we will need sponge-backed discs or polyester film.

3. Embossing level: type of material to be sanded

In this case we can speak of two clearly differentiated types of materials:

Embossing materials: for which we have abrasive discs that have a spaced or semi-spaced distribution of the mineral, in addition to a layer of anti-embossing stearate.

Slightly clogging materials: this time we will use abrasive discs with a semi-spaced or closed mineral distribution depending on the type of material to be sanded.

4. Hardness of the material to be sanded

Hard and tough materials, such as steels or alloys. We must use abrasive discs with ceramic ore, compact ore or zirconium ore. On occasions in which the development of the work will be carried out in areas with high temperatures on the surface, we must opt for abrasive discs that contain a layer of active lubricant.

Highly hard materials such as stone, glass or ceramic. In this case, we will use abrasive discs with silicon carbide ore.

Materials with a medium or low hardness. Use abrasive discs with aluminum oxide mineral. Maybe you're interested: Wind turbine repair: how to rebuild damage to materials

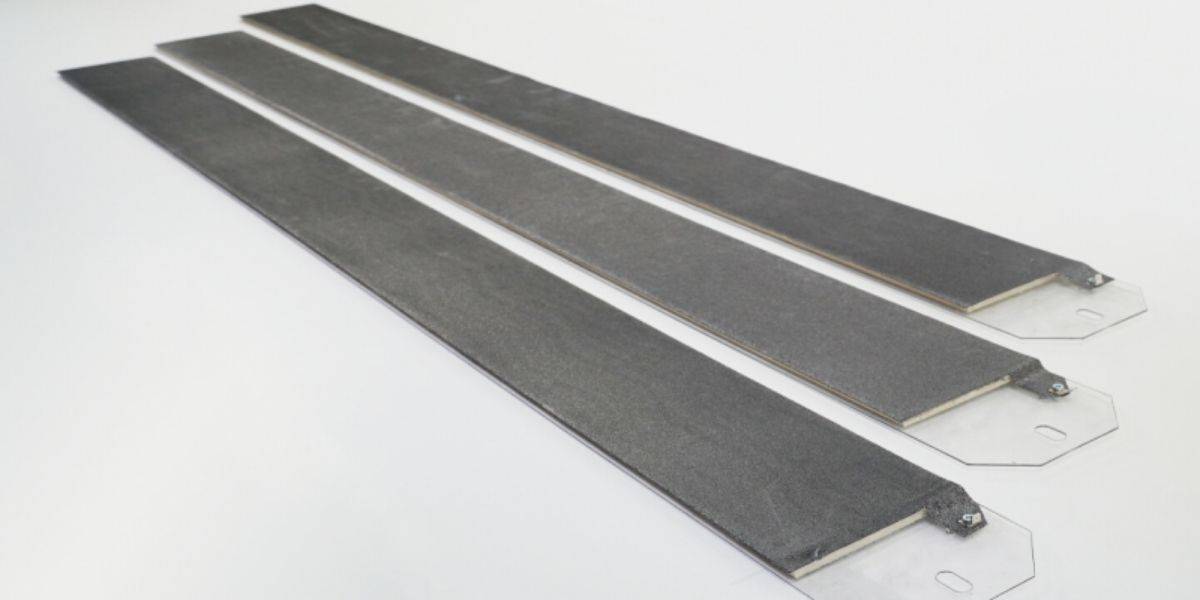

How to choose custom abrasive bands

In this case, we will focus on wide bands, those whose measurements are greater than 600 mm and up to 1,600 mm.

These types of bands are used in the wood and varnished sector for sanding flat pieces.

When choosing an abrasive belt there are different variables to consider:

1. The appropriate mineral for the type of material we want to sand:

Zirconium ore should be used to sand hardwoods in rough calibration or surface sanding operations.

Aluminum oxide is the most common mineral used for sanding wood, veneer and melamine, in any sanding operation.

Silicon carbide ore is used to sand fiber boards, particle boards and solid surface

plates.As for the sanding of primers, sealants and bottoms, it is possible to choose between the use of the aluminum oxide ore or silicon carbide, depending on the type of

bottom and the sanding operation, although in general the silicon carbide is The most

employed.

2. The distribution of the mineral is linked to the level of embouchure and hardness that the sanded surface presents.

Therefore, it is necessary to take this particularity into account when opting for one type of band or another.Distribution of spaced ore: use for sanding soft and/or resinous materials prone to rapid swelling of the abrasive belt.

Distribution of semi-spaced ore, for sanding wood, veneers, melamines, as well as primers and sealants in varnishing.

Closed ore distribution. Use on fiber boards and chipboard boards.

3. Existence of stearates to reduce embossing and improve the level of finish.

In this way, it is possible to choose between different types of bands:Bands without stearate, used for general sanding of wood, veneer, melamines and

boards.Bands with stearate, used for sanding putties, bottoms and solid surface in general.

4. Take into account whether the abrasive belt is antistatic or not.

Since it is a feature especially relevant in the case of continuous sanding and varnishing lines, in which the pieces are sanded and immediately after they are anchored and finished.

Although, the antistatic bands prevent the dust released from sanding from electrostatic energy and easily adhere to the piece before varnishing.5. Support used for abrasive tape.

Keep in mind that the choice of the type of support is determined by the type of operation to

be performed.Calibration and sanding operations use bands with rigid cotton fabric support, or cotton with polyester or polyester only if the aggressiveness of the calibration operation requires it.

Coarse or intermediate sanding operations, which involve the use of bands with rigid

paper support weight F which allows proper planning of the sanded surface.Fine sanding or finishing operations, use bands with semi-rigid paper support weight E

that allows transmitting the flexibility and sanding pressure of the sanding units with

sectioned skid group.Superfinishing sanding operations, use narrow belts with polyester film supports to

achieve uniform sanding and free of emboss marks.To choose the appropriate abrasive bands we must consider the appropriate mineral, the level of embossment and surface hardness, the existence of stearates, if the band is antistatic and the support used for it

Why with Abracom

At Abracom we are highly specialized in the customized transformation of coated abrasive products for the industry: rolls, discs and abrasive bands. We have the specific abrasive for each material and sanding operation. We advise our clients to recommend the abrasive products that best suit their needs. Contact us and we will advise you.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)