¿Necesitas un lijado de precisión sin dañar superficies delicadas? Descubre las ventajas del disco de espuma estándar...

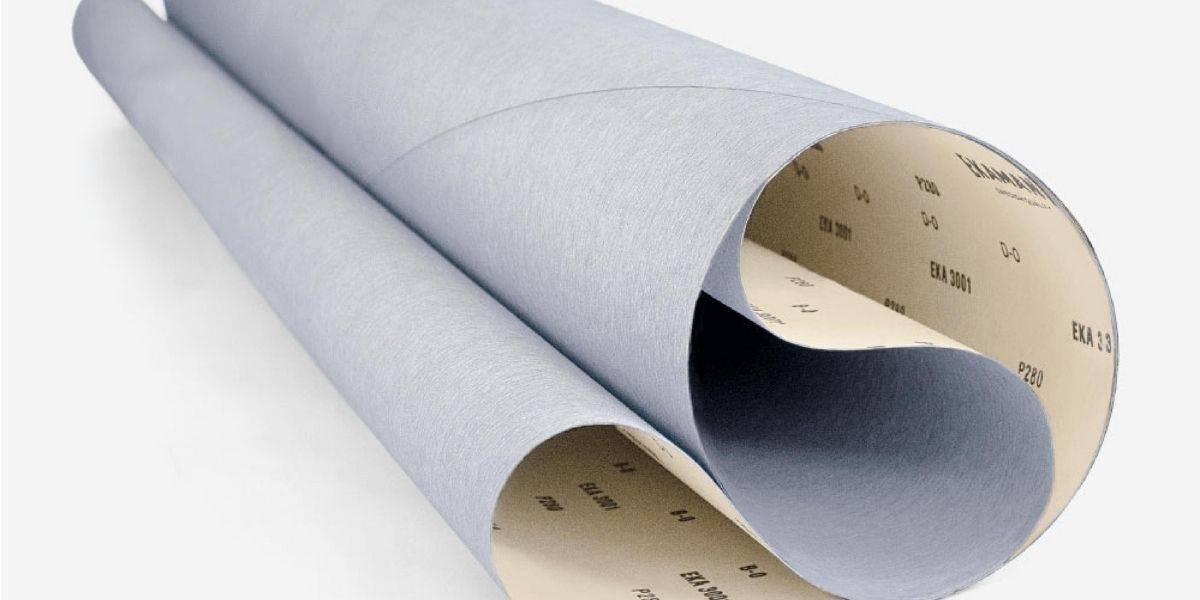

}The operation of an abrasive belt is based on the continuous rotation of its surface on two rollers, in order to level surfaces by removing large amounts of material. With this, we will obtain excellent results on a large number of surfaces and in a short time.

Of course, as long as we choose the appropriate type of belt in each case. As logically, it does not require the same to remove scratches from a piece of furniture than to sharpen a blade or obtain a micro-finish on a fiber optic material. We invite you to know which sandpaper belt to choose depending on what your need is.

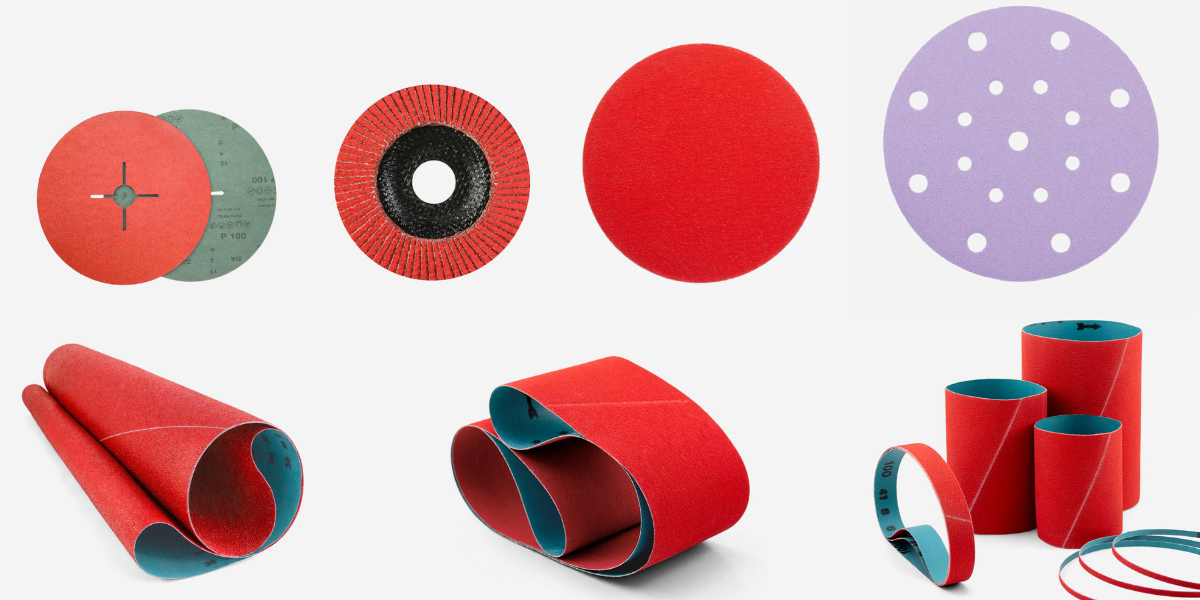

Types of sanding belts and their uses

Long belt

The long and wide abrasive belts are ideal for edge sanders. They are considered as such when they exceed 3,001 mm in length. Its applications can be exploited on veneered surfaces, on plywood, and hard and softwoods. They can be used in all sanding methods, such as finishing or sizing.

Short belt

The short belts have a belt length from 690 mm to 3,000 mm. Highly refractory materials and stainless steel (INOX) can be used for sanding, as well as for aggressive sanding with maximum starting capacity on hard materials that are poorly conductive of heat.

Transverse belt

These types of belts have many uses; It can be used for the intermediate sanding of industrial lacquer systems, for the rectification of lacquer defects, for the rectification and tinting of primers or to section the vertical pile of the wood. It is also useful in intermediate sanding of thin layers of varnish or, with finer grains, for use on oily surfaces, treating high-gloss varnishes, rectifying lacquer defects and preparing for polishing on high-gloss surfaces.

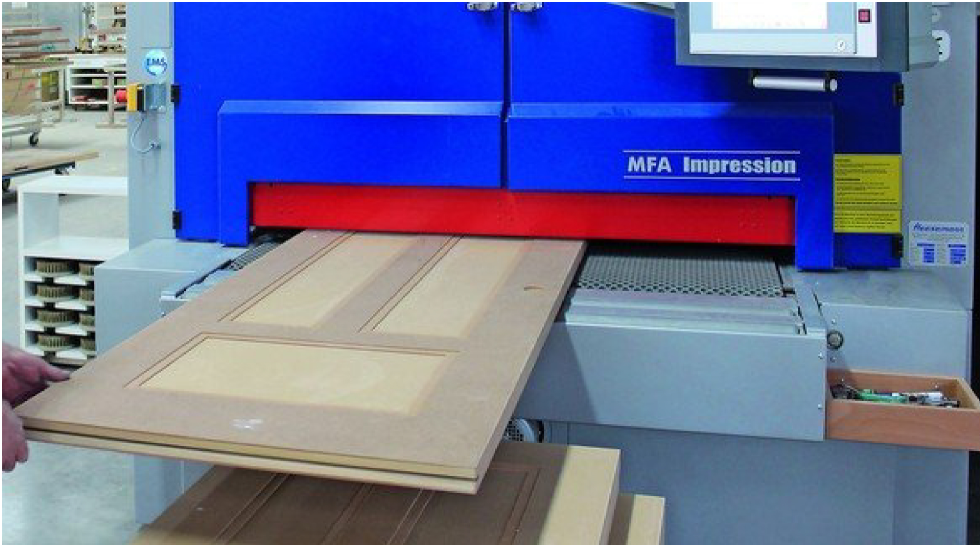

Broadbelt

Wide belts are those that even go up to 1500 mm wide. They are used predominantly in the wood industry, for the removal of varnish defects, intermediate sanding in industrial varnish systems and sanding of high wood fibers, as well as for the grinding and shading of primers, intermediate sanding of thin layers of varnish and the final sanding to prepare the polish, among others.

Sanding belt materials

Together with the abrasive material or granular surface, the other component that makes up the sandpaper is the support or backing. This can be made of cloth or paper, although there is also plastic film.

Rigid, semi-flexible and flexible fabrics

Cloth backings provide strength and long life, as well as allowing bending and flexing while in use without reducing performance. In the case of being flexible, it is ideal for providing finish and uniformity, even on curved surfaces. It is used in belt, sheet and roll sandpaper. The semi-flexible cloth backing, for belts and discs, is used both for removing coarse-grained material and for fine-grained finishing and polishing. Rigid cloth for heavy-duty industrial belt sanding is used to remove heavy material, which requires coarse grain applied with high pressure.

Rigid papers

Paper has the advantage over rigid fabrics that it is cheaper, although it has the disadvantage that it is so resistant. However, we can find support materials with greater durability, it is in the case of that support that is marketed to be used with power tools.

Other kinds of sanding belts

There is a type of sanding belt and belt for sanders to cover every need. For this reason, on the market you can find, for example, portable belts, which are designed for all types of interventions on wooden surfaces and as sanding belts for metal. They are distributed in different sizes, to be able to be used in different types of machines. Sanding sleeves, on the other hand, are abrasive cloth tapes that are wound onto a cotton backing and are used for specific places that are difficult to reach, such as edges of concave sections.

Finally, the cooling cross belts, with a cloth and felt supports, are also used for specific uses. Abracom is a highly specialized manufacturer in the production and commercialization of the tailored belts necessary in each case. Thanks to its experience, its team of professionals and new and flexible machinery, it offers the best solutions for sanding all types of surfaces.

At Abracom we are passionate about what we do. If you want to know more about us or our products, do not hesitate to visit our website and contact us.

.png)

.jpg)